Hey folks, Phil Zito here and welcome back! In today’s post, we're going to be discussing how to properly review, scope, and estimate BAS projects. Today’s post was part of a Podcast/YouTube combination we did where I broke out our whiteboard to show you how this process works. Don’t worry, I will explain it in great detail for you and you can always check out the video here as well.

So, this is important. It's something that often is taught but it's taught in silos. When I see new sales folks getting onboarded, where they're taught how to review, scope, and estimate, oftentimes, they're not taught these things in a logical series. In such a way, as you're doing this process, you see how the things interrelate, because really doing the review, scope, and estimation process, especially for construction projects, is an iterative process.

So, what that means is that you iterate through, usually several times, where you will perform a review, then you will do a scope based on that review, and you'll do an estimate. As you're doing that, you're going to find yourself having to typically re-review, adjust scopes, and adjust estimates as you discover more information. But more importantly, as you go through, especially with new construction projects, there's this thing called SD’s, DD’s and CD’s, and these are the types of documents, and the phases of the documents, that are being created in a construction environment.

So basically, you have a project that gets tendered, and once the project is funded, you have GC, you have an engineer, you have an architect, and you're creating these design documents. The two primary design documents we're going to focus in on are going to be your MEP, mechanical electrical plumbing drawings, and then your specifications. Now I'm going to be focused on Masterformat CSI, which is used here heavily in the United States. So, I'm going to be focused primarily on Division 23, which is our primary division for building automation.

That being said, as these documents are developed, you start off with a building intent, then you get a little bit more definition on that building intent. By the time you hit this CD phase, this construction drawing phase, you end up with actual documents that tell you what you should be doing in regard to how you're going to build the actual project and execute everything from installation details, sequence of operations, equipment schedules, bill of materials, notes, details, etc.

If you are engaging in SDs, then your scopes are going to be pretty loose, your estimates are going to be pretty loose. You're in SD’s, you're in DD’s, and you're in CD’s, right? Well in SD’s, your scope and your estimates are going to be really loose. Then as you move closer to that CD phase, your scopes and your estimates are going to get much tighter. So, you need to be cognizant of that.

Now typically, during a new construction project, you're going to be in 50, to 75, to almost 100% CD's when you're estimating. Now what does that mean? Well, from a percentage perspective, there's this thing called, POC, percentage of completion, and it's all over the place. This can be based on billings; this can be based on tangible execution of tasks. So, you can say, when the equipment schedule is built out, that is a certain percentage.

It can be defined as certain tasks, as billings, etc. So once that percent of completion is near 75% or greater, the amount of scope change that you're going to be running into, isn't that great. Now, I will tell you that in the SD and DD phases, in my experience, changes in the percent of completion can have dramatic effects on scoping. But when we get to the CD phase, typically all the equipment is selected, and now we're just talking placement, as in location or routing of ductwork, things like that which doesn't significantly affect our bill of materials, as well as the selection of our products. So, our scope does not change substantially. Now, there are issues that can come up in CD phase related to things like integration of BACnet via gateways on chillers, things like that.

Okay, so now with that whole premise defined, and I feel like we are all on the same page, in regard to our project flow, the different phases of projects, the different types of delivery models, projects, now we can look into how we actually execute our process. We’re going to go through review, we're going to go through scope, and we're going to go through estimate.

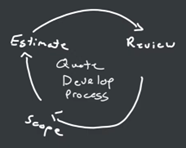

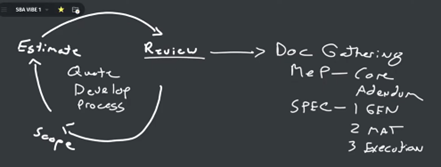

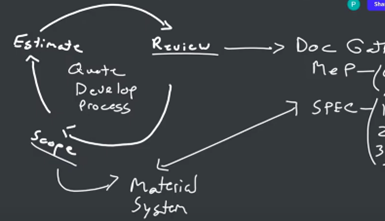

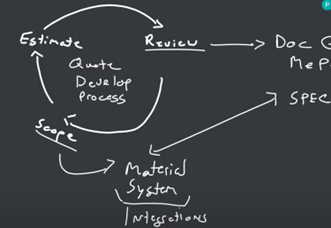

As I mentioned, we have this circular process. So, on our whiteboard, I'm drawing a circle with arrows on it, and that circle has Review, Scope, and Estimate written on it. This is what we call the Quote Development Process.

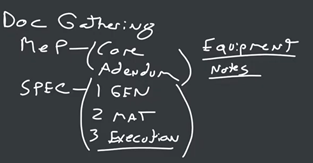

What happens here in this development process is first we have Review, and as part of the review, whether you're in new construction or an existing building, you're going to want to do document gathering. What do we want to gather? As I mentioned earlier, we want to get our MEP set and those MEP sets will have our core sets, and then they'll have any addendums. Then we'll have our spec, and with our spec, there are three categories: Gen, Material/Products, and Execution. Some specs have four, and the fourth would be typically around validation of the actual implementation.

We have Core and Addendum. What we're specifically focused on here with the MEP core and addendum, from our gathering perspective and our review perspective, is on our equipment schedule. Our equipment schedule is going to list out our terminal unit schedule, it's going to list out our air handlers and our chillers. Typically, we'll have model numbers, especially if we're in the CD phase and equipment has been selected. Once we have that information, then we're able to really start to build out our scope, which we'll get to in just a second.

So, we have our equipment, and then any addendums to that equipment. Specifically, we also want to focus in on any notes, because notes will typically call out the division that's responsible. These are things that people, who are newer to sales, don't tend to catch, such as, “Actuators are furnished by controls contractor, installed by mechanical.” So, you have to cover the product cost for the actuators, but the actual installation is potentially covered by the mechanicals. So that affects your costing.

Additionally, things like factory package terminal units, where you're going to send the controls to the terminal unit manufacturer, and then they're going to actually take their terminal unit and controls, put it all together and ship it out to you. So, now all you have is the controller cost, and you don't have that installation cost.

In specification, this is going to be really specific when we get into our estimating. This is typically going to call out things like, “These are the products. These are the related sections that you need to refer to that may have scope that you're held liable to. This is where you'll find general conditions,” and all this information.

The material is going to specify the specific type of material you have to use. Sometimes it'll just be something as simple as, “Use a 4 to 20,” or, “Use a 0 to 10 type sensor.” Other times it'll tell you the exact sensor you need to use.

Execution is going to come into your estimating and tell you things like, “Do I need to support commissioning? Do I need support test and balance? How do I need to do my submittals? How are things going to be validated?” It may have sequence of operations. The execution may actually be opposed to the MEP, and you may have to put in some clarifications in the scenario. So just be aware of that as well.

Now we're going to look at the scope. So, you've went through, you've done review, and now we're doing scope. So, scope is where we're going to build out our scope and our scope is going to come to us from the MEP core and addendum equipment lists, typically. We're going to build out our scope and understand if we are attaching to an existing control system, a new control system, what material, etc. So we're basically going to start to build out a system list.

I tend to like to start from the terminal unit level and work up, and here's why. When I start with the terminal unit level and I work up, what happens is that I have this terminal unit and then maybe I have 50 terminal units on the floor. That then helps me size my supervisory devices and my server. So, I'm able to work up.

I like to go with terminal units, their supporting air handler. Then once I have that done, then I'll typically do a chiller and a boiler that support that air handler, if necessary. That will work for the majority of buildings.

Once I've done material on systems, then I will do any integrations or any related specifications. Things I like to check for are if I’m using BACnet cards, if there is the factory-package controls, if there are things that are furnished by others, or things I'm furnishing and not installing. I like to understand that. Then once I have all of this information, I can actually do my estimate.

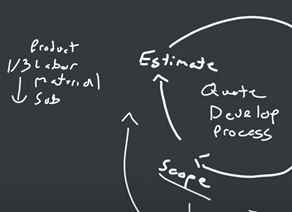

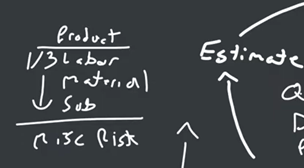

Now, here's where I do product selection. So, I select my products based on my scope that I just built out, and I start to assign the trifecta of labor, material and subcontracted costs. There's the rule of thirds, which is that on any given project, most of them will break out into a 1/3 labor, 1/3 material, and a 1/3 subcontractor cost. Now, if you self-execute, then that labor will typically be combined with subcontractor costs, subs typically being the electrical subs. If you don't self-execute electrical, then the 1/3 law will typically follow.

Now I am seeing the shift, as we tend to move toward more material intensive, via integrations, and less install labor intensive. So, we are seeing that shift. But for an average product, that's a good check point for you to identify if your costs are wonky.

What you'll also do with your costs here is you'll identify that you have your labor, your material, your sub, and then you’ll do your miscellaneous costs, your risk, prevailing wages, if you have that. If you have things like any permits that you have to do, you'll do that, as well as any travel costs. All of this will get buttoned into here.

Now, during this scope and estimating process here, you may find that something's unclear. You may have to submit an RFI, request for information, or an RFC, request for clarification. That RFI or RFC is going to then give you further clarity, at which point you'll adjust your scope and your estimate.

So, that is the Review, Scope, and Estimate process. I hope it gives you some clarity around how to approach sales. If you are looking to dive deeper into this, we do our BAS Scoping and Estimating Mastery Bootcamp course that covers it.

Thanks so much for being here. Take care.

-May-12-2022-08-38-25-55-PM.png)

-May-09-2022-08-17-01-32-PM.png)

-May-24-2022-07-01-28-30-PM.png)