Hey folks, Phil Zito here and welcome back. In this post, we are going to be diving into plan and spec documents. We're going to cover how to review them. What do we look for? What are the different parts and pieces of them? How are they structured? So, we're gonna have some fun.

We’re going to begin with a high-level kind of discussion of specs, and we're going to talk about mechanical plans. Now, specs and mechanical plans are developed post-tender. So, tender is the funding of the job, and then you select your contractors, your general, your engineer, etc. So, what happens is, you create documentation based on the owners’ intent of whatever this project is.

So, we typically start with a kind of site drawing, a vision, which will turn into architectural drawings, which then will turn into the mechanical, electrical, plumbing, drawings. Now, drawings typically go through three phases before they're released to construction.

- Schematic Design

- Design Development Phase

- Construction Design

So, SD, DD, and CD. What happens is, you move through these and you may hear like, 50%, DD, that may be a term you hear. That means the drawings are 50% design development phase. So how I like to explain this is that the schematic design is like laying out the skeleton, the development design is like the muscles, the circulatory system, etc, and then the construction design is like putting on the skin.

To give you a better example of this is, if you've ever worked on building your own home, or you've been involved in maybe building your own home, you start off working with an architect. You create your vision, then you get the schematic design, which is the general layout, what's the orientation of your house, etc. Then you move on to design development, which is where you start to lay out floor plans, and then construction design gets into the specific details of the actual layout, like where's the HVAC ducting, where's the lighting, etc, where all this stuff goes so that it can be released to construction and built.

Now that is also true of specifications. So, whereas the drawings provide a visual representation, and we can kind of see that right here, they provide a visual representation of where mechanical, electrical and plumbing systems go.

The specification provides the details as to the requirements, both from an execution perspective as well as from a product selection perspective and a phased implementation perspective. This will all make a lot more sense as we go through these.

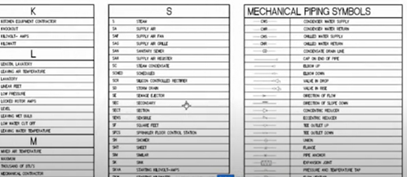

So, first things first, we have a mechanical plan here. Now what you'll typically see we're going to go front to back, and we're going to start with the front page of mechanical.

So, what you typically see is a symbol listing as well as an abbreviation listing. This is where, it'll tell you what these symbols mean. These are the representations of the symbols, as you can see. We also can see any abbreviations and what they mean.

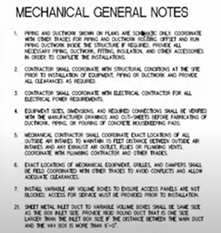

We'll also have our general notes that will discuss any general notes related to mechanical systems that we may need to know. How these pages are going to be laid out is we're going to have a page right here. So, it's going to be Mechanical 01.

Sometimes there is an actual Table of Contents, but there's a different word for it, and it’ll list out what the pages are. As you can see, we'll move into the 100s, and then we'll move into the 200s, which are typically our floor plans. Then we will move into the 400s, which are typically going to be mechanical details, as well as our schedules. Then we'll start to move into your flow diagrams, which are going to be our 5 series right here.

Okay, now, let's take a second and look at specs and then we'll dive deep into each one of these documents. So, specification is is based on CSI MasterFormat, and you can tell this is the more current spec standard because we're Div 23, division 23, Section 09 00.

Now what we see here is a section called General. This is typically going to give a narrative of what systems are included, base of design, related sections, etc. Then we will eventually get to Section 2, which is products and or materials. So, this is typically called products, and/or materials.

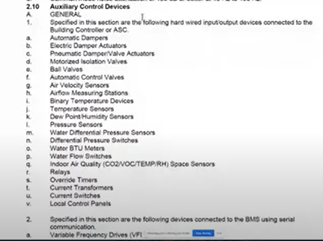

What this will list out is basically a very detailed explanation of materials that go into the project. This will be everything from communication trunk standards, controller type standards, panel standards, and then once you move from that, you will actually start to transition out of the controllers into the IO, which they call auxiliary control devices. This is where we will find our standards around valve types, damper types, IO, inputs and outputs, sensor types, etc.

Then eventually, we'll get to Part 3, which is typically called Execution. This will talk about the execution of the project. So, whereas General will typically get into submittal and initiation, Part 3 will typically talk about execution.

So, how do we coordinate? How do we validate? Then how do we ensure proper operation of the system, sequence of operations? Then how do we close out the project.? So, we'll see all of this kind of come together.

So, let's start with mechanical plans. All right, as I mentioned, Table of Contents, Mechanical General Notes, Abbreviations, not much here. I mean, once you've looked at enough drawings, you start to recognize, that's a valve, that's a control valve, etc. The area I like to really focus in on is the General Notes because notes can sometimes conflict with spec expectations.

One thing I want you to think of is, for every negative that I'm going to cover today, there is also an opposite positive. So, for example, “Div 23, mechanical contractor shall coordinate with electrical contractor prior to actual installation of temperature, humidity, and carbon dioxide sensors.” So, why would this matter and where does this coordination come in play?

Well, picture this. The building’s being built, slab gets poured, stubs are put in and walls start getting put up. Then, just then you decide to get with your electrical sub, have them go out and start putting in the sensors. Well, if you had actually coordinated with the electrical contractor, you might have been able to get some stub ups in the mechanical rooms and in the slab. You may have been able to coordinate some potential stubs for your electrical that are in your walls, etc. I mean, it really just depends what's in scope for people.

This coordination is going to save you relocation, and quite honestly, I would say that Div 23, it's not always the mechanical, it can sometimes be building automation. So, I would coordinate not only with electrical, but would probably coordinate with mechanical as well as to accurate locations. We've all been there, where something is being built, and then all of a sudden a electrical panel is placed right where your thermostat is supposed to be and you have to relocate.

Let's see if there's anything else popping out. Nothing really that pops out, but testing and balancing, “Contractor shall provide all necessary testing and balancing for the project.” So, that's something I'd want to kind of understand. Granted, this says this is the mechanical plan. So, I would assume that means the mechanical.

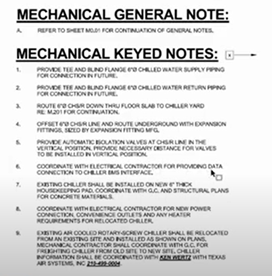

Alright, so we get into our General plan right here and we look to see if there's some stuff that has anything to do with us.

I mean, “Coordinate with electrical contractor for providing data connection to the chiller BMS interface.” That's pretty important one, right? We've all been there where someone didn't catch the BACnet card and so it was provided without a BACnet card. In this job, there's an existing chiller, so we need to coordinate to run some electrical wiring out to this. That would be something that we would want to be aware of, right.

So, at this point, I'm just going through notes. So, when I look at a plan, the first thing I do is I go through all of the notes, and I make notes of the notes. Anything that potentially could involve me, you know, data to the chiller, something about automatic isolation valves, right? This information would be important to know, especially from providing valves. Then, once I've gone through the notes, I like to go to my Equipment Schedule, and with my equipment schedule, I start to build a rough bill of materials. I start to kind of understand, this is what I have on the job.

So, right here I'm seeing I have variable air volume boxes with electric heat, it's SCR, so silicon-controlled rectifier which means 0 to 10 signal, and also some other notes, “control shall be provided”. So, I can offset some costs by having the terminal unit manufacturer mount my controllers as well as providing the transformer. So, I can start to see some information. I start to make notes of all of this, right.

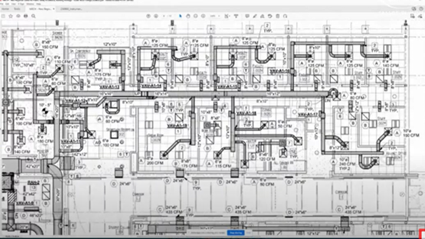

Once I've made notes of this, and I built out a list of materials and a list of systems, then I go to my floorplan and I start to figure out, how is this going to kind of lay out?

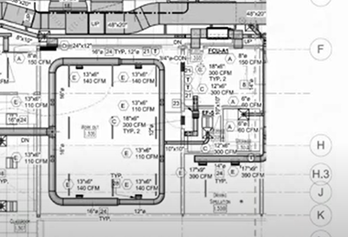

So, I have my VAV boxes, kind of figureout how I'm going to lay them out. I try to find my General Mechanical room.

I also try to see, there's something right there that I'm going to potentially need to control. So, right now I'm just trying to get a snapshot. So far, I'm in pre-sales, and I'm estimating. We had a question specifically about this asking, “On average, how long should it take the project estimator to read and understand specs and drawings?”

Well, it depends, right? It's not a cookie cutter answer. This one right here would probably take me an hour or two to go through, just because there's so many related sections in the spec, but it's not a matter of time. Although time is important, it's a matter of accuracy. What I mean by that is, I would rather you spend an extra four hours being accurate and win a project because you realize, these are all BACnet cards on all these air handlers, and thus I don't need to provide controllers, than you just rush through it and miss something like that.

Some of the common misses that I see are people missing who includes mechanical materials, like sometimes the valves and actuators are included by others installed by controls contractor, or included by controls contractor installed by others. That's something you need to catch. Integrations are a big thing to catch as well as being able to use controllers for other systems that may be nearby.

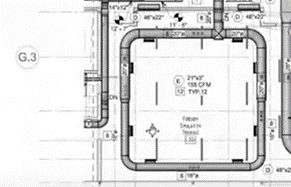

Right here, we see we have a mechanical plan with a fan coil unit, exhaust fan, then we have our air handling unit right here. As we actually go in here, and we look at this, we see our mechanical plan, and we see a note right here, Note 10. See that square box right here Note 10.

So, if I go over to Note 10, I'll notice, “Approximate location of DDC panel to be mounted…” If I were to read more of the notes, I could find out that “AHU VFDs to be wall mounted and installed by electrical contractor”. So, we know that the electrical is actually running and installing these and we're going to need to coordinate with them. These are all things I have to start thinking through.

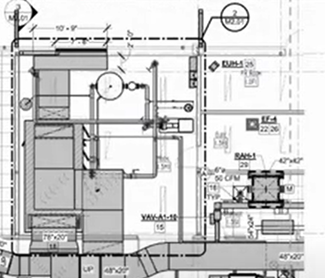

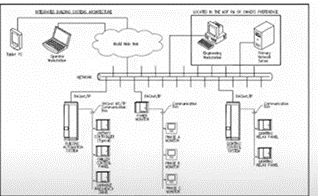

Mechanical plans aren't terribly difficult to digest. There are some things that are unique to this plan that I don't see in a lot of plans. They do a pretty good, detailed drawing of the BAS network, and I don't typically see this.

The one thing I will caution you on is if you do happen to see a controls schematic, or you see a sequence on a mechanical drawing and you see a controls one line, this is still something that I would be careful of. As you start to get the equipment submittals and you read through the specification, things may actually be a little different. This is called a one line because if you draw it, it's one line, and then you have your control devices.

This actually calls out that there's an AO, there’s AIs, there’s BOs. This one, actually, has a different sequence for this air handler, this mixed air, single path air handler. They have a different sequence here than they do in the specification. If we read the specification, there are minor differences in how the spec reads out versus how this reads out. That would lead you to a Request for Information/Request for Clarification to figure out which one of these takes precedence.

So, regarding the question, I don't have a hard-set rule on time, but I do have a hard set rule on accuracy. I have to be able to honestly ask myself, if someone set this set of drawings aside after I reviewed it, could I legitimately tell them the systems that are there and who is providing the parts and pieces for the systems? Could I tell them if there are any unique integrations? If I can, after looking at the drawings, answer those questions and answer them accurately, then I know I did a good job. That actually will pay more than trying to slim a day off your time, because yes, maybe you'll get through more estimates.

Do you want to have more accurate estimates, thus, you can be at a lower cost, and you can win more jobs? Or do you want to be getting more estimates out the door, but they may not be accurate? They either may not be winning your jobs, or if they do win your jobs, they may be costing your company margin due to slippage and missed things. It's a balance, right, and it's something that just comes with time, unfortunately.

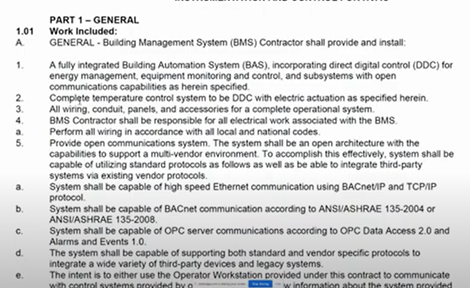

Let's go into the spec now and let's walk through this. So, Part 1-General, this is going to say some really obvious stuff.

“We're going to give a building automation system”. Oh, really? That's surprising. “We're going to control the DDC”. Okay, great. “BMS contractor shall be responsible for all electric work associated with the BMS”. So, right off the bat, you should wonder, I see this, but then I also see that the electrical sub is responsible for VFDs. So, you're starting to see the conflict there.

This is an area where you'd have to ask yourself, Do I RFI this? Do I just accept that in common sense land this means obviously, wiring up my controllers, wiring up my trunk, wiring up my IO, or do you actually clarify this more? It depends on the customer.

When I'm doing government work, schoolwork, stuff like that, where they have a very heavy hand, they have ability to really come after you if you get something wrong. I tend to like to be clear on everything. If I'm doing more commercial work, and I know that this person probably just wants a system that works, then I know if it says all electrical work, I can reasonably assume that it means IO field controllers. Your general rule of thumb for this is, this applies to the information in this portion of the spec.

“Provide open communications system with multiple vendors”. Okay. BACnet. Okay. OPC, this is a little interesting. Why do we need OPC? Do they have some form of SCADA system? OPC is kind of more of SCADA-ish controls protocol. So, I'd be interested in that.

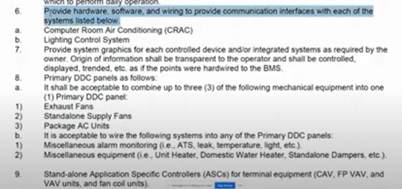

Moving on, “Provide hardware, software and wiring to provide communication interfaces with each of the systems listed below”. This is kind of my first red flag here that I really want to understand. “Computer Room, air conditioning, lighting control system.”

So, typically, the first thing I do when I see any form of integration, is I'm going to look for related sections.

I don't see anything about lighting or CRAC units. I guess you could argue central HVAC would be crack units, or maybe decentralized HVAC. “Products integrated to but not installed: lighting control”. So, I want to understand, how am I supposed to integrate with this lighting system?

There are three types of integration, right? Physical, protocol, and programmatic. Primarily most of you are going to be doing protocol integration to lighting systems, BACnet chillers, etc. You're going to be doing physical to like fire alarm, things like that. Programmatic is going to be like weather stations, scheduling systems, etc.

Moving along, so we have some things we just want a red flag here. We have to integrate to CRACs, which is most mostly a Liebert Sitelink, or something like that. Lighting control system, that's typically going to be like a BACnet integration, something like that.

We see that we have a DDC system. “Primary DDC panel”. This is where I was talking about where panels combine. So, this is kind of right here, we're seeing this shall be acceptable.

We're going to combine these pieces together into a single panel. So, they just gave us an approval to do that and some miscellaneous monitoring. “Automatic Transfer Switch (ATS), leak detection, temperature lighting”. I don't like that this is has the etc in here.

![]()

The risk adverse side of me likes to have stuff pretty well lined out, but I also realize that this is one of those things that you know, you just have to accept.

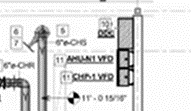

Alright, so we have some ASCs. That's a BACnet term. BTL for application specific controllers. That's going to be our “CAV, FP VAV, or fan power VAV, and VAV units”. That's going to be important later in this post, because we're going to see that it's going to call for BACnet IP controls, but then it's going to call for a secondary network with ASCs. Those BACnet IP controls are going to be AACs. So, we're going to see that for like our air handling unit. Then we're going to see that these more terminal units are going to be ASCs, which are BACnet/MSTP controllers.

General Product Description goes through some basic stuff. It's pretty straightforward, common-sense stuff.

“Products furnished but not installed”.

Here's that wording that I talked about, that we also see in mechanical drawings. Furnished but not installed, meaning that we are furnishing, but we're not necessarily installing. Now, where you have to be careful, and this bites people in the butt sometimes, is they say, “I'm furnishing this, which means I am providing it. I'm including the cost in my estimate.” Then they skip over the related section that says you're also installing it. So, they assume when they read this, they don't have to carry the install cost, but because they didn't look at the related section that said they have this related cost, they end up getting bit in the butt.

So, you can typically assume most of this is installed by the mechanical and the plumbing. Airflow stations and pressure sensors, they're hit or miss whether you have to install them.

Then we see “Installed but not furnished”.

This is something that tends to be a little safer but is also at risk of you being held liable for, you know, you're installing this, but you also have to provide.

“Products integrated to,” you're usually pretty safe on this, except for things like “variable frequency drives”, or if it were to say like flow sensors, etc. Lighting control you're almost never going to carry. You're just going to integrate with.

![]()

I will take a brief moment to touch on integration. Integration is something that you want to be cognizant of because the lighting manufacturer, or the access control, or whoever, may think that they are the lead in the sequence. You may think you're the lead of the sequence. Then you have what are called competing leads. That's where the building automation system schedules the lighting on, but then the lighting system schedules the lighting on and they conflict and you get this kind of Christmas tree effect where the lights are off, then the lights are on,then they’re off, then they’re on. So you just need to be cognizant of that. Whenever I see integration to another system, I want to know who is going to be the lead system.

We already covered related sections, so we’ll move to Approved System Contractors.

We see this one, Siemens. This is where you would submit, if you really wanted this work, an add alternate for your control system. It never hurts to submit an add alternate, especially if it's a publicly procured system. They tend to take that. So you know, just because you see someone as the standard, do not hesitate to do an add alternate.

“Quality Assurance,” I mean, basic stuff, right?

People, people need to have a service organization, list of 10 projects, etc. This is standard stuff that gets put in to try to exclude the smaller businesses. Some standard stuff around UL categories, some standard stuff around ISO, some standard stuff around codes.

Now we get to submittals. So, this is the first opportunity for you to start revenuing in business. You need to think of your project as its own profit and loss center, its own P&L, and your goal is to get that project cashflow positive as quick as possible. So, you're drawing on the cash revenue from the project and not from the business, because then that frees the business's cash up in order to allow it to reinvest in marketing, and sales efforts, and growth efforts.

Additionally, if you're working for a large corporation, and you're a branch office, oftentimes, there's an interest charge on any cash that's provided to the branch office. So, you want to try to work off your own internal cash as much as possible.

Well, submittals, as I said, they're the first opportunity for you to make money because once you submit, you can bill out typically, percent of completion, typically 10-20% on the project. So, you can bill out with this right? So, I like to pay specific attention to the order that things need to be in. What documents do I need to provide? What are they expecting to see? Then what format does it need to be in? Does it need to be an 11x17, or maybe 36x24? Does it need to be electronic? I've seen submittals rejected for stupid stuff, like they wanted 11x17 landscape and you did 11x17 different layout. So, don't get your submittals rejected, because you don't read stuff and understand like the basic of basic.

Then once it gets through the submittal, it talks about demonstration, talks about what you're going to do with your demonstration, and then it talks about your as-builts and your project record documents.

Please don't get your final 10% on the project held up because you don't submit as-builts the proper way

Please don't get your final 10% on the project held up because you don't submit as-builts the proper way

Next it talks about testing and commissioning reports, O&M manuals, all that fun stuff. Then we have “Warranty”.

It talks about your response, so you can start to figure out how much warranty costs do I want to go in? What can I do here?

Next is “Products”. I have a love/hate relationship with products. I love that products is included, and it makes my job easier, as an estimator and a designer, to be able to look at the products and know that's going to be an Onicon dual turbine flow meter, or that's going to be a Setera, adjustable airflow meter. On the flip side, and we'll see this in this spec, you can get some products requirements that are a little bit ridiculous. We'll see that when we get towards the IO portion of the spec.

But suffice to say, most of the time, products will list out materials, you note that it says here, “Spare parts should be available”. So basically, they're saying, don't use brand new stuff, because it's not a test site, but also don't use stuff that's end of life in two months. This is not such a big deal on like commercial or schoolwork that is going to be executed in a very compressed timeframe. If you're working on like a master plan response, maybe for an airport, or something like Hudson Yards, you want to consider that your design, and your spec, and your submission may not actually be implemented for 18 months, so, you would need to take product lifecycle into account. Most folks aren't going to run into that.

“Communication,” this just lists out how we are going to communicate. This one talks about a bunch of IP stuff, it’s basically saying you need an IP network for the supervisory device and your central plant and air handler controllers. That's called the primary network. Then you'll see your secondary network which is ASC.

Here's where the nonobservant person could get really hosed. Now granted, this is flat spec Siemens, so I wouldn't expect them to mess up considering it's a flat spec. But imagine this being an open spec, and multiple bidders and multiple vendors are on this, and they don't catch that there's a secondary network for the ASCs, application specific controllers. They don't catch that it's RS-485. What is RS-485? That is the wiring and communication standard on which BACnet/MSTP and Modbus RTU are built. This is BACnet MSTP.

You also know that they're doing a big no-no in here. Maximum 96 TECs on an individual secondary network. I know that you can do it, but just because you can doesn't mean you should. If you've followed me for any amount of time, if you follow the RS-485 standards, 64 devices, 32 on each segment, that you're not going to get in trouble. As soon as you go above 64, you risk data issues.

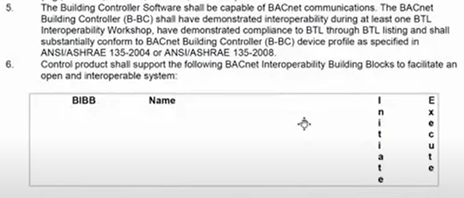

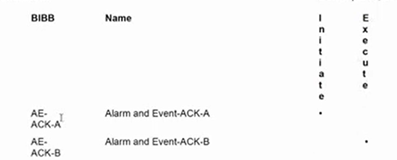

“Building Controller Software”. This is all just listing out BACnet stuff, BIBBs and BTL and BACnet profiles.

Quick point on BACnet, see that A and B?

We have Initiate, so client. Execute, server. That's what I was talking about when I said you have devices that can either be a client and/or be a server, so they can be both. Clients initiate the services, and servers execute the services.

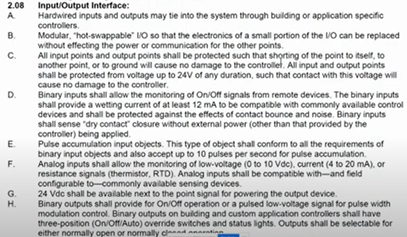

Alright, so this talks about the inputs and outputs of the controller, but I want the I/O devices.

Ok, “Temperature Sensors. All temperature sensors shall use platinum RTD elements only”, okay, and “4-20 mA loop”.

Alright, so if you’ve been through my course on design and hardware selection, you've seen this before because this is this spec we use in that course. It provides a very good example of, if you don't catch this, and you assume reasonably that you're working with a school, and schools are usually cost sensitive, there's no logical reason for platinum RTDs and 4-20 signals. That adds probably $30 to $40 per sensor. So, this is something that you say, if I have 1000 sensors here, and I can potentially RFI this with an alternate of a nickel, resistive 1k RTD or 10k type T thermistor, whatever and get it approved, you've just dropped your material cost by $30,000. When you apply margin on top of it, that may be, you know, $35-$40,000. You've just made yourself much more cost competitive.

So, it's important to read through these not just from a selection perspective, not just saying, I'm going to select my materials. It's also from a cost perspective and a strategy perspective.

Finally, once we get through here, we built out our mechanical list. We've built out our list of equipment, we've started to build out our BoM. So we've said, we have zone temp, we have discharge temp, etc. It's now at this point, that we say, we can pick the specific devices, we can start to figure out what exactly do we need with our devices. I'll look at things like an airflow pressure switch.

So, this is a “differential pressure switch, diaphragm type, switches shall be single pole double throw, used for fan status”, so I could probably use the DP series of the Cleveland controls, instead of the AFS series. Actually, I think these have to be adjustable. So, I may have to use the AFS series. So yeah, these are things you can figure out because the difference between the DP series and the AFS series of the Cleveland control can be like $20 a sensor. So, if you have a lot of these, that can add up.

Let's get down to “Execution” now.

So, at this point, we've read through the mechanical, we've read through our general and our materials, and now we're ready to understand our execution so we can properly estimate our labor. This is where we'll know if we have to support a commissioning agent. Do we have to carry a laptop around for the test and balance folks? Is there some extent to owner training? What do we need to do?

All of this is what I already told you, we just need to basically figure out our locations for some answers. We have to verify anything that we're going to wire up. We need to examine our stuff and make sure that it is compliant to ADA, compliant to space requirements, etc.

“Protection”, we need to make sure it's protected. Now this reminds me of Grand Prairie Police Station in Dallas, Texas. They had three Daikin units, and I don't know who left the door open to the Daikan units, but someone did during construction, and like this crazy storm came through and blew water all over the control section. I'm pretty sure it wasn’t us who left it open, but we got blamed for it and they wanted us to pay the cost of replacing the integration cards and the Daikan units because they got rained. So, there was a big back and forth about that because of this right here, this protection.

“Coordination” just means you're going to show up at the meetings, you're going to coordinate your schedules. I've hammered this so much in our past posts. Please show up to the initiation meetings, please work with your electrical folks reiterate that we need this on, we need this working, this is our Gantt chart that shows if you give us power on this date, it's going to take us this many days to do XYZ.

“Test and balance”. This means we have a single set of tools.

So, we need to provide a laptop. We need to train them on that laptop. And there it is, “The contractor shall provide a qualified technician for duration of 8 hours to assist in the test and balance process”. So, we have to provide a laptop, it has to have our software on it. We want to create some test and balance graphics to make their life easy, and we have to spend four hours training these folks. Then we have to do eight hours of assistance. So, account for that your cost?

“General Workmanship”, this is the basic stuff, install stuff. Make sure it's wired good. You know, all those things.

“Communication wiring”:

“Installation of Sensors”, this is basic stuff. Go through it with your electrical sub, make sure they understand what this all means.

Ok, so now we have “Programming”, and it's going to talk about how you need to name, how you program, so you’re programming. This is just basic stuff, right?

User Interfaces, provide graphics, I'd pay attention to “Standard graphics”. Understand what they expect. Understand, you know, right here, this highlighted section where it talks about installing, starting up, troubleshooting, operators. So, this is the IT stuff, making sure it all works.

Prior to acceptance, we have to do a bunch of tests. Then we have to do some control system check out, and we have to have the engineer observe this stuff.

So, it looks like there's some commissioning, and it looks like it has to be two people going through and doing the stuff. It also looks like there is seasonal changeover. So, you might have to come back halfway through the season. Then finally, it talks about the different performance tests, we're going to have to do, loop response, optimal start, logs, cleaning basic stuff. Then there’s training.

We have to provide training. What do we have to provide training on?

It needs to cover all these things. I don't normally see this in here. Normally it’s kind of just hit or miss.

Finally, it’s “SOP”. What is our SOP? Does our SOP match our mechanical drawings?

There you have it, folks. That is mechanical plans and specifications 101. I hope you learned something. I know this was a much longer post, but I think it was worth it. I don't think you're going to find much information like this anywhere else. So, I hope you took some stuff out of this. Be sure to leave any questions or comments you may have about any of this information and material. I love to respond to your thoughts.

Thank you so much for being here. Take care.

-1.png)