How to Optimize Your Building Systems

Well it's good to be back!

I've been away from writing this summer and one of the reasons why is that I recently got asked to become the Program Manager for our Healthcare Environment Optimization (HEO) Offering. This was and is an exciting change for me as I have always liked Program Management.

In addition to this, I took a new role as the Integration Program Manager for our Building Wide Systems Integration Program Management Office (talk about a mouthful!)

Because I am now tasked with creating innovative solutions that can help our customers integrate building systems together I am able to work on some interesting stuff. During this post I am going to give an overview of what the Healthcare Environment Optimization solution is. I believe this is one of the best ways to illustrate the concepts I am discussing . My goal here is not to sell you on my employers solution. There are multiple solutions out there that do similar things.

Rather, my goal here is to discuss the concept of utilizing your existing systems to produce outcomes that impact your business. With that being said, when you read this article you will learn:

- What Real Optimization Looks Like

- How you can Optimize Your Building with Your Existing Controls System

As you can see this article is about more than Healthcare Environment Optimization. In my role I work with hundreds of complex buildings each year and it still amazes me how many building owners aren't utilizing their building systems to the best of their ability. I understand that integration is complicated, my hopes are that you will leave this article understanding how to optimize your building systems.

Now with that diatribe done, let's get to the main course...

What Does Real Optimization Look Like?

Optimization is more than just a decrease in energy or an increase in "efficiency". After all I can decrease the energy of a building by turning all of its systems off. However, those within the building probably wouldn't feel very "optimal". According to Websters Dictionary the definition of optimization is

An act, process, or methodology of making something (as a design, system, or decision) as fully perfect, functional, or effective as possible;

My definition is simpler than that. I believe that optimization is a process or change that adds value to the business. Ultimately business value is what sells "optimization" to the higher level executives who decide whether or not to fund ideas.

The HEO offering I was asked to manage is a perfect example of optimization. At first glance the idea of optimizing the Operating Room seems like a good idea. After all, who wouldn't want to "optimize" their operating rooms. However, just saying I'm gonna optimize your OR doesn't get folks pulling out their check books. In order to get a change funded you need to be more granular. And that brings us to Phil's first rule of optimization and integration.

Find the Change that has a Business Impact and Sell it

In the case of the HEO offering we started off trying to sell all of the benefits to the clinician, pointing out how you could log the conditions of the environment and how you could give the clinical staff greater control. However, when presented with this option the owner simply could not articulate that value. It wasn't until we looked at how optimizing the airflow in the OR could save a quantifiable amount of energy that we found a change that had business impact.

Right now Healthcare is under a budget crunch and the OR is a substantial portion of that budget. By identifying an area where we could save a measurable amount of money for the client we were able to find the business impact and communicate it in a way that showed value to our clients.

So what exactly did we do? Well the good news is we didn't do anything earth shattering. We simply found a way to optimize the building using the existing controls system. Unfortunately I can't go into the technical details without losing my job. What I can do however, is describe other ways in which you can optimize your building and that takes us to....

How can you Optimize Your Building with Your Existing Controls System ?

Analyzing What You Have

The first step in any optimization or integration strategy is to understand what you actually have within your building. That may seem easy but y0u would be shocked (well maybe you would..) as to how many buildings do not have accurate representations of the technology that exists within their building.

So how do you analyze what you have? I like to follow a structure similar to the OSI model, starting with the hardware and working my way up the stack to the software. I divide my analysis across four main "Systems":

- Physical Systems

- Network Systems

- Storage Systems

- Software Systems

Physical Systems

Physical systems are compromised of the actual systems that exist. For example, you have a Alerton Building Automation System, Lutron Lighting System, Oracle Database System, ect. Do not mistake a physical system for being a physical device. I know this may be confusing to some but it makes sense to me. As I often say, take what works for you and throw away the rest.

Network Systems

Network systems should not to be confused with a Cisco System or a Juniper System. Those would be physical systems. The network system is the actual network structure. Questions like what is the location of switches, does the customer have a distributed core network, what does the edge of the network look like, are there off-site network services, ect. If the physical systems are the limbs the network systems are the arteries.

Storage Systems

Storage systems are the database structures, schemas, and formats. What are the database tables for the Physical Systems for example, we know that the Physical Systems consist of a SQL and a MS Access database, but the storage system defines the data tables, what is the structure of the database, what are the primary and foreign keys, how is the data exchanged. Keeping with our body part theme Storage Systems would be the neurological connections of your building.

Software Systems

Now within the physical systems you may have defined that you have a Server 2012 Operating System, here you breakdown those systems to understand what services, connections, and capabilities you have. For example, if you are building a integration that relies on a MVC application but the IIS cluster is isolated on another network from the systems in question then you may have some issues unless you want to do some fancy routing (for those less techie folks, what I am saying here is if the software is not accessible by your other systems and vice versa than you may be limited in your ability to integrate).

Identifying where you could optimize

If that all seems like a lot of information to gather, I hate to break it to you, it is. And that is why you need to identify where you could optimize to help you narrow down any further analysis. For my example I am going use a College Campus that has abnormally high energy bills in one building because the professors have unscheduled events and neglect to turn the space off after the event. In this case you first need to identify the systems involved in this issue.

Physical Systems

The Physical Systems as I see them could be:

- HVAC

- Lighting

- Audio-Visual

- Network

- Scheduling

Network Systems

With these Physical Systems identified, I next move to identify the Network Systems. I discover that the HVAC, Lighting, and A/V are all on their own Network Fundamentals. The network consists of a distribution switch, a few access switches, a wireless access point, and a few different virtual LANs.

Storage Systems

Next I move onto the Storage Systems. In this process I identify that the HVAC, Lighting, and A/V all share a Learning SQL database. The scheduling software utilizes a Key - Value Database. Knowing this we have identified the first integration point.

We could if we want create a normalization table to take the Scheduling software database and the HVAC, Lighting, A/V database and "combine" or normalize their schedules.

Software Systems

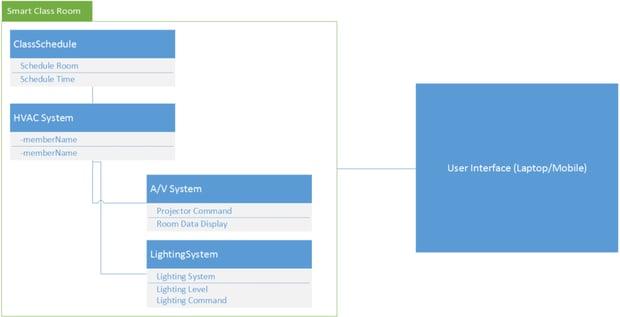

Finally we have the Software Systems. These systems are the final part of the optimization process. It is here that we combine all of the previous systems to produce our "optimized system". It is at the Software System level that we would write integration code, combine code libraries and develop the integrated logic that will produce our outcome. Below represents graphically what this may look like.

This view is at a high-level as to be understood by my entire audience but essentially what is going on is this.

- I am taking the Schedule Command, via HTTP or some for of RESTful feed from my scheduling software and pulling it into the HVAC system. I am using a HTTP to BACnet/IP (or equiv) gateway to translate this schedule to override the schedule for the HVAC system.

- Next I take the scheduled data and I feed it to the A/V system which then powers up the A/V devices and powers up the digital signage.

- Finally I turn on the auxiliary lighting systems.

- Next all of this is fed back into a responsive mobile User Interface that utilizing an authentication source like AD or OAuth is able to authenticate users and then allow authenticated users to access the lighting, A/V, and Temperature controls for their particular room via their smartphone. All of this is surprisingly easy to setup and with the right components it would take a matter of a few weeks to prototype out onto a MVC friendly website.

Side Note: If my readers are interested in me going deeper into the nuts and bolts of building out an integration like this let me know in the comments and I will write an article that discusses architecting an integration in greater detail.

Convincing folks to buy into the optimization concept

So you have prototyped your proof-of-concept integration and now you must gain the backing of executives in order to fund your project. This is the part where a lot of technical folks struggle and it is where I have made my career toeing the line between technical laymen and sales person. The process of effectively communicating how your solution will provide value is really simple.

First you need to identify your strategic initiatives.

Do you have a sustainability or energy savings goal? If so you can focus your solution on realizing that goal. You would first need to baseline traditional utilization of the space and the cost of this utilization. Once that is done you will need to estimate the savings from the "optimized" utilization rate.

You compare these savings to the forecasted cost and create a Return on Investment or (ROI). Using the ROI you can now generate a cash-flow model that will allow you to represent the internal rate of return and show the value of the investment compared to other choices. With this information at hand, you will create an executive summary of your integration and present that to the key stakeholders.

Conclusion

We covered a lot of ground in this article.

First, we walked through a real-life integrated offering and how that offering could optimize your operating rooms. Next, we dived into my methodology for surveying and identifying existing systems. Finally, we discussed how to create an optimized solution and how to sell the solution to executives in order to gain funding.

What is your take on my approach?

How do you Survey your Existing Systems?

In what interesting ways have you combined your existing systems to optimize your buildings?

What questions do you have about integration?

Let me know your questions and your answers in the comments below!