Hey folks! Phil Zito here, Phil Zito here and welcome back! In this post, we're going to talk about how to incorporate training with work while staying profitable.

Alright, so I was on a call today debriefing with some managers from our Workforce Development Program, and we were talking about how they incorporate training with their work, and not just tank a job. Here's the deal, you could take someone who needs to learn a skill, you can put them on a job, and you can “train” them. But those often tend to be double-whammy scenarios.

What will happen is, your senior technician, the person who is running the job or is the lead tech on the job, that person is now splitting their profitability between training this employee who is probably operating at 20-30% efficiency and working on their daily work. So, now you have this high paid senior technician who probably is not trained on how to train people and they are sitting there trying to train this person, oversee OJT, as well as work on a project. Then you have this person on the project, who potentially is not being efficient. So, it's kind of a double whammy when it comes to a profit hit.

You know, you'd be better off if you didn't put this person on the job, because ultimately, yeah, you may be generating more revenue, but you're not generating profit. So, how in the world can you train people when a lot of what we do requires, hands on work, while not taking your jobs?

This has been a problem that our company has been noodling on, and I believe we have the solution. While we definitely have a product, like everything, that you all can buy that will solve this, I want to talk to you about how to do it yourself.

So, first things first, when most people try to implement some form of OJT or incorporate training with job work, what they tend to do is they take this omnibus unstructured approach. They think back to, what did I need to know as a technician, or what did I typically do? And that's if they're thinking. Sometimes, they're not even thinking at all. They're just saying, “Oh, crap, we're behind on this job. Let's take these two new hires we've got and let's stick them out on the project, and whatever the senior tech needs, that senior tech can have those people do.”

While that is the most inefficient way of doing things, that is the reality as to how a lot of people do things. So, what can we do to fix that? Well, first, we have to separate from the premise that we're just going to put someone out there, and that there's no way of structuring this training, and that we just have to accept that people are going to be inefficient and we're going to have a decrease in efficiency.

I'm going to start with the premise that we can actually implement training in project work, and we could do it profitably. We can have a net profit with the project while doing it. So, how do we do that?

Well, the first thing we have to do is a job task breakdown. So, in order for us to do any form of training, and to tie that training to OJT, it requires us to have a job task breakdown. So, like I said, just recapping quickly from the previous post, we take a job description, we do a job task breakdown, we figure out what tasks contribute the most to profit and to project execution. Then, those are the tasks we're going to train and focus on.

Now, when we want to incorporate training with work and we want to stay profitable, then we need to be able to target work opportunities that have enough of the work that we can quickly train someone to do to an average level of performance that then they can use that performance on the job to kind of take them from average to above average, to excellent performance.

Just for metrics sake, average performance would be 50% effectiveness, above average would be 75% effectiveness, and excellent performance would be 90 to 95% effectiveness measured in estimated versus actual executed hours allocated to a task.

So, for example, if you have someone, and you've estimated 4 hours for a VAV box, but they take 8, that is a 50% effectiveness, right, because they're 50% off. So, right there, if we are able to improve that to 6 hours, that is now 75% effectiveness, and if we're able to improve it to like 4.25 hours, that is now a 90 to 95% effectiveness. So, those are the metrics we're going to use when I talk about using metrics.

Okay, so we've laid out this framework, and we have our job task breakdowns, and we're going to identify jobs that have the tasks that we're looking for. So, this is a combination of having processes, having procedures, and having job tasks. So, job tasks we've broken out, like I mentioned in the previous post, processes and procedures, we're going to break out in this one.

So, you should have, for example, using this VAV box example again, a process for doing VAV box installation. You should have a procedure. The big difference between a process and a procedure is a process is kind of high level, whereas a procedure is going to be step-by-step.

So, what you're going to do is you're going to train on the procedure, and you're going to have them implement the process, which is a list of procedures. So, for example, our list of procedures for the VAV box install may be mounting the controller. Just mounting the controller is a procedure, it is part of a larger process.

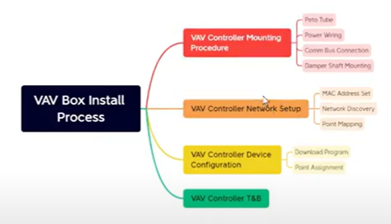

So, the larger process can best be understood this way. Below is my favorite software that I have mentioned in the past. This is the mind-mapping software I use, and it is extremely helpful when trying to understand our procedures and processes.

So, we’ll label this VAV Box Install Process, and then I would have a procedure for each one. I would have VAV Controller Mounting Procedure, and this procedure may include like, the Peto Tube, maybe it includes Power Wiring, maybe it includes Comm Bus Connection, and maybe it also includes Damper Shaft Mounting.

Then maybe we have another procedure, which is VAV Controller Network Setup. This procedure may include MAC Address Set, Network Discovery and maybe Point Mapping.

Our next procedure could be VAV Controller Device Configuration and may include Download Program and Point Assignment. Our last procedure could be VAV Controller T&B.

So, we're doing all these things, and we're coming up with these procedures. Now I know you're saying to yourself, “Phil, this isn't our procedure.” I mean, what we would ultimately do is, I would open up a Word file, and detail out everything they need to do.

So, I’d start with, “Take controller mount horizontally using applied VAV controller hardware,” and I'm just totally spitballing on this. Then we would have like a little video, and it would show someone doing just that little piece. Then it would be, “Connect Peto tubing to VAV integral airflow sensor,” followed by a diagram or some little screenshot.

We would do this and then it would get stored on like a SharePoint site, or on some sort of website. Then the technician would be able to pull these with their associated videos, and we'd be able to watch all these procedures. The process would be another document that would be labeled, and then you would have a procedure for each process.

Now you have this person, and maybe there's 1000 VAV boxes on this project, and they follow this process. By the time they've done 1000 VAV boxes, within the first 100 VAV boxes, they're going to go from probably 50 to 75% efficiency. You see that see that average to above average proficiency gain, that happens pretty quickly, but it's the above average to excellent, that's the one that takes a little bit longer.

If you can get somebody who's 75% efficient at doing VAV boxes, and they are brand new to the field, and you're paying them maybe $40-$50,000 a year, that is potentially, and you'd have to crunch the math, that is potentially a better payoff than a senior tech who's 90% efficient, but you're paying them $90-$110,000 a year.

I mean, if we crunched the numbers and I did 40,000 x .75, that's 30,000. Right? So, we're losing 10,000, but we're keeping 30,000. Now, if I go again, and I take someone who is 110,000 at 90% efficient, that’s 110,000 x .90, that’s 99,000, so it's basically the same loss, right?

With the brand-new technician, you have a $10,000 loss, and with a senior technician, you have a $10,000 loss, but the senior technician is doing much less detailed and difficult work. It's much easier to train up a brand new technician to do a VAV box install than it is to go and find someone who can do complex central utility plant programming, right.

You can use this same process here, and this is what's so powerful, is you can use the same process again and again. You create an install process, you create the procedures, you train in-house quickly, you document these procedures, and you videotape the training, and you create this procedure document. Then you have them execute this in the field. This isn’t just for VAV boxes, right? You could do this for design, you could do this for programming, troubleshooting, you can create literal processes and procedures for almost anything.

Now the trick is, where do you go and put your dollars? You know, when do you decide that you want to put your dollars to a specific process development? This is why I highly recommend you do job task analysis, and you measure job tasks. If you notice that you have a huge inefficiency in your install job tasks and focus in on your install processes, then getting those trained up and developed is going to be very effective.

For example, if you have70% efficiency on install tasks, but 90% efficiency on programming tasks, then it makes no sense to work on programming tasks. It makes sense to work on install tasks. What I tend to find, is because a lot of organizations do not have the skills to evaluate these, that's why they turned to us, so what I find is that the organizations tend to apply an equal weight to every task. Actually, sometimes they apply an unequal weight to tasks based on perceived exertion or biases.

Now what do I mean by that? So, a perceived exertion is going to be, “I perceive programming to be much harder, and I perceive it to be a much higher skill, therefore, it needs more training focus.” When in actuality, if you followed any of our programming podcasts or our programming videos, you realize that programming is nothing but a series of processes of implementing the correct design patterns, based on what you're reading in the sequence. It can actually be quite easy. I know that is sacrilege to say, but it is what it is.

Now, what do I mean by biases? Biases is, especially in this day and age is a hugely loaded term, if you've always been a programmer, and you moved into ops management, and you were always a programmer, then quite often your bias is going to be that programming is where you should focus. If you came from the field as an installer, installation is going to be where you're biased; you're going to focus on installation.

So, the ability to be aware of that perceived exertion and that bias, at the same time, is going to help you. I was talking to my Director of Sales today, and we were talking about sales performance and how can we measure the performance of our sales team. We were talking about taking emotions, biases and beliefs, out of it and dealing with facts. You deal with facts with numbers, things that you can quantitate.

So, by using job tasks, by measuring job tasks, and doing postmortems on projects, based on this job task codes, you can see where the deviations exist. So, this becomes a very important way of measuring performance. Once you've measured performance, then it is simply a matter of implementing processes.

So, to recap on implementing these processes, what you need to do is you need to identify job task breakdowns, from your job descriptions. Once you've done that, then you need to say, these are the metrics we're going to measure these job tasks by, start measuring them and within, you know, a good summer season, you should have a pretty good idea on performance.

Once you have an idea on performance, then you could say, if we improved this job task or that job task, it would have a disproportionate result. And that's the key, right? If you notice that you have 30% efficiency on VAV boxes, but 80% efficiency on plant design, then it may make sense, based on how many VAV boxes are on jobs, to implement a VAV box training program, of which you decide on your company's internal process.

I would argue that there are two VAV box install processes. There's a VAV box install process for factory mounted VAV controls, and there's a VAV box install process for non-factory mounted VAV box controls. So, you develop those two processes, and with those two processes, you develop procedures, realizing that a lot of the procedures are going to overlap. For example, the VAV controller network setup procedure, the VAV controller device configuration procedure, and the VAV controller test and balance procedure are going to overlap, whether it is a factory installed VAV controller or a non-factory installed VAV controller.

If you take that 30%, and you're able to increase it to 75% efficiency, that is much greater than increasing that central plant, which arguably, is more complex, but at the same time there's less of them and increasing that by 10% efficiency is not going to have near the payoff.

That's where a lot of these people make mistakes with their training. They just simply look at taking this OEM class, or doing a generic training, and they don't tie it to performance. Tie it to performance, measure the data, look for low hanging fruit, grab that low hanging fruit, increase efficiency using a process and procedures, and then you're going to see dramatic growth in your profitability. With profitability growths, as long as you're not taking huge owner draws, then you should be being able to reinvest that cash flow into the business, thus growing the business substantially.

I have a sneaking suspicion that with the way the economy is going, the need to evaluate processes, and really squeeze efficiency out of every opportunity we have, is going to be a primary focus. Those of you that are ahead of the curve, that are focusing on process efficiency, are going to be in a much better place when stuff starts to contract and get tight.

Alright folks, as always, if you have any questions do not hesitate to reach out to us. Like I mentioned, this is a service we do provide and assist our customers with. Feel free to learn more by contacting us.

Thanks a ton and take care.

.png)

.png)

-Aug-30-2022-08-58-10-21-PM.png)