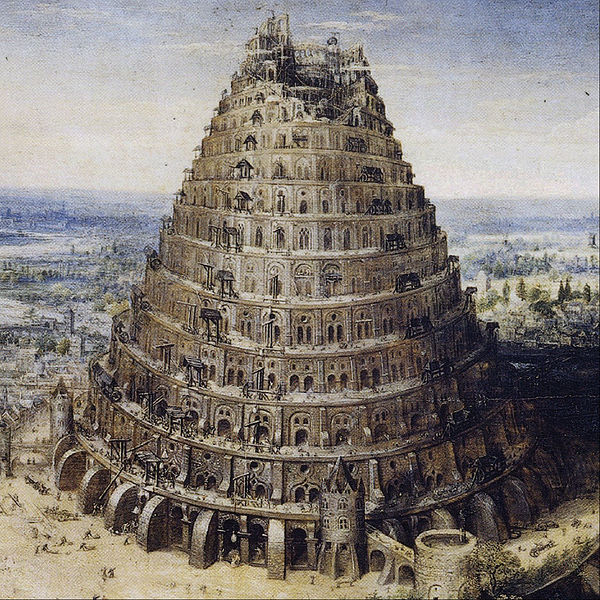

Is your control system becoming the next Tower of Babel?

BACnet, LON, Obix, M-Bus and P-Bus... There is a veritable alphabet soup of controls protocols and systems within the market place and although the industry is moving towards an open framework, we still have a ways to go.

In this article, we will discuss the ramifications of value engineering and multi-vendor deployments within the building automation space. At the end of this article you will have the foundation to effectively manage the sourcing and selection of controls systems throughout your enterprise.

It Starts With One

Most building owners are looking for reliable control and comfort at a reasonable price. Once the decision has been made to either upgrade or install a DDC system the owner faces his/her first major challenge. "What System do I Select?" is the question that is usually asked and typically the answer depends upon three key factors:

- The owners experience with a product

- The consulting engineer's experience with a product

- The products price

It is here that we begin to see our first major problem. Ask yourself, what business outcomes were included in the three key factors? What if the customer is running a Tier 4 data center and needs a product with built-in N+1 redundancy? What if the site is under FDA regulations and requires a validated environment and the product does not support that.

All to often what customers get is just the continuation of a cookie cutter specification given to the consulting engineer by a local product sales person. In my world we call these guide specs and they exist to guide the engineer into specifying your product.

You might be asking "So then Mr. Smartypants what should a customer be concerned with?" Here are the top 5 concerns, as expressed to me by experienced buyers, when making an initial purchase:

- What are my core business functions?

- How is my business profitable?

- How do I run my facilities?

- How likely am I to expand my facilities in the future?

- Are there any special regulatory or compliance concerns?

For instance, let's say you are a Fortune 1000 company you have 10 global manufacturing facilities and 8 regional buildings essentially comprised of commercial real estate. You are selecting a controls system for your local manufacturing facility.

What are my core business functions?

In answering the first question you would say, I need to reliably produce a product in my facility, ensure up-time, and be able to interface with my SCADA/ICS systems to understand Key Performance Indicators (KPI)'s relative to my business. However, if you stopped at this point you would be neglecting the other side of your business.

In your regional buildings you need to provide environmental conditions that are comfortable to your occupants and you also need to run HVAC systems. These systems are quite different from the ICS/SCADA systems that exist within your factories.

How is my business profitable?

Where does the money come from? If your primary revenue source comes from your manufacturing facilities then it might, just maybe, make sense to invest in a bit more than a programmable thermostat for your control system. Furthermore if you have multiple lines would it be beneficial to have the same control system in each line so that your controls group only has to know one product?

How do I run my facilities?

Do you have your own staff or do you outsource? Do you sell your assets (facilities) within a few years or do you run them until the building collapses? Knowing how you operate your facilities determines how you purchase controls and setup your systems. I have been to too many sites that run buildings for 30 years without a M&V or energy management plan. When asked why they weren't managing their energy the common response was "It was to expensive to add meters to our BAS after fact." One of these customers, we later found out, was being over billed 200k/yr by the utility provider.

How likely am I to expand my facilities in the future?

If your facilities are likely to never expand and you do not have any special requirements then by all means go out and purchase whatever system is the cheapest and does what you want. However, if you have multiple facilities or complex facilities you need to create a matrix to align your needs with the capabilities of your potential provider. Do not rely on your consultant to do this for you. All to often they have a specification created years ago that they plug your project in and then rely on vendors to meet the intent of the specification. This is a terrible way to select a provider.

Now, note, there are plenty of consultants that really "know their stuff". However, there are also consultants who tell the controls technician that it is their job to write the sequence of operations for the central plant because they "only do rooftops"....

Are there any special regulatory or compliance concerns?

FDA, CDC, DOE, in the world of building automation it's not the four letter words that get you in trouble its the three-letter acronyms.

Certain markets have specific requirements on reporting, compliance, and auditing. For example, you could go purchase x,y,z system for your food production plant only to find out that the product you purchased does not have an audit trail built-in and just like that you are out of compliance with the FDA.

So we discussed a single building now lets shake up our crystal ball and look into the future at a company who didn't heed the advice above.

Now its Twenty

Fast-forward several years, the economy has been good to you. Customers wanted your widget and your focus quickly shifted to how can I increase my production capacity and provide building space for the support staff that followed. Little thought was given to the standardization of control and specifications were largely developed at the local level. You now have a variety of ICS and BAS systems inside your facilities. Some systems speak BACnet some Lon, and you have some old Teletrol system that you inherited when you bought the building and then... it happens.

You get pulled into a meeting to discuss the decline in profits, your competitors have caught up and now things are getting hairy. Cost of production becomes a key factor. Every form of waste and inefficiency needs to be evaluated and you have been asked to provide key metrics to the executive team by next quarter so they can drive the business through what is now becoming a mature market. Herein lies the problem. Every system you have speaks a different language and yet you need all these systems to talk. YOU NEED THIS DATA!

So what do you do, your first response would be to call a systems integrator and depending on the product he/she represents what you will be told will sound something like this.

"We can pull all your open protocol systems into our xyz widget and then your older systems will either need to be upgraded or will need to be replaced."

You now sit there mouth agape wondering how you got to this point and imaging how you will explain a capital project that could number in the hundreds of thousands if not millions, to your executive staff.

What to Do?

What to do indeed. I meet with customers everyday who find themselves saturated in the alphabet soup of providers and protocols and in fairness as much of the onus lies on the consultant as it does the owner. In today's hustle bustle world of business the desire to think strategically and to deliver a solution that will span an enterprise is rare, if it existed in the first place.

Consultants are being hammered to deliver a specification that is cost effective and fits within a budget. We live in the age of value engineering with all relevant efficiencies being drawn out of a project only to be installed post-construction at a substantial premium.

A change is afoot, systems integrators and controls savvy professionals are moving into the consulting space. Systems are becoming more open and vendor agnostic. However, the same problem remains which is the lack to effectively plan. Here are the three key things you must decide in order to ensure that your post installation costs remain manageable.

- Decide on a protocol not a product. Rather then selecting abc company. Select BACnet or LON. Enforce your solution providers to provide protocol native platforms. This frees you to select any product within that protocol sphere.

- If you can afford it stick with one product. If you stick with one product then you only need to stock parts for one system and you only need to train your team for one offering. This plays well with teams that self execute and have expertise in-house.

- Know your business If you are going to flip your building in 2-3 years then purchase electro-mechanical thermostats not a full-fledged DDC system. Spend your money in practical ways that align with your business. However, if you are holding your assets for more than 5 years take the time to create a master plan for your facilities. You have 10 year strategic markers, shouldn't you have a 10 year facility plan?

This is Just The Beginning

I wish I could say that with technology all the issues we talked about will become a thing of the past. The reality is the marketplace will continue to become more saturated. We are living in the age of choices, when I go shopping I literally have a choice of 100 different toothpastes.

How do you stay educated?

How do you know you made the right choice?

Well my friends you are making the right choice by being here, my hope, better yet my passion is to share knowledge and educate the industry as a whole.

That requires participation, I took the time to research and write this article, now I encourage you to comment below, tell us your story, and share your wisdom for the betterment of us all.