Imagine an employee who works 24 hours a day never stopping, not requiring benefits, with the ability to clearly communicate the needs of your organization to hundreds if not thousands of employees at the same time. Do you see him?

The new employee of the 21st century may not be visible to the naked eye but trust me he's there. According to the MIT Sloan Management Review as of March 2013, 67% of companies are using analytics to gain a competitive edge. That represents a growth of 15% from 2012 and 80% from 2011, so to all the naysayers out there, the growth is real and the growth is present.

One of the constant challenges within the workplace is finding, training, and retaining quality employees that produce measurable impacts upon a business year over year. Businesses are now able to generate next-level results using analytics and are starting to deploy analytical systems into other functional areas. One of the functional areas, building operations , upon which this site focuses, will be the focus of this article.

How Did we Get Here

The trend of analytics started within the financial sector. Financial organizations realizing that the massive amount of data from primary, secondary, and tertiary sources were becoming so overwhelming decided that simply adding manpower to their staff would not effectively handle the need to interpret and react effectively to a 24/7 feed of multi-vectored data.

With the rise of networks, most noticeably the internet, financial organizations were now able to process large mounds of data using statistical analysis to pinpoint correlations in data which exposed red herrings, false presumptions, and bad predictions. Furthermore, the systems allowed the organizations to quickly create projection models resulting in an increased ability effectively plan and forecast.

Naturally, other businesses and entrepreneurs began to take notice of the power of analytics and we began to see a on-rush of analytical systems. Business processes, supply chain management, and CRM were now being converted to utilize analytical platforms.

With this new-found knowledge business leaders could pinpoint target markets, impact cost of operations, and streamline supply chain processes. As technology continued to grow the analytical systems became more robust, the issue then became data storage. Systems could process so much raw data that a need for data storage became a driving factor and with that systems began to move to the cloud.

Cloud technology seems like such an amorphous term, the average person when they hear the word "cloud" has many thoughts some positive and some negative. In order to dispel the myths it's important to realize that cloud technology is really no different then on-site storage or on-site computing, the only difference is that it is off-site. However, for some this is a big difference.

While data security and routing are outside the scope of this article, suffice to say the amount of security in cloud systems, like, such as Amazon Cloud or Microsoft Azure rivals that of some governmental organizations. Often times security risks, if they occur at all, are due to lack of proper IT processes at the business itself.

What Difference Do Analytics Make?

What difference indeed, that is the question. A better question would be what difference are analytics not making because I am not using them. I was sitting with one of our best sales people in my company and he said to me "Phil, what will be the impact for a customer if they go with our analytical software and more specifically How will that impact their FTE's because at the end of the day someone has to use the tool". First, off there is nothing like a good sales person to ask a non-technical business question that really makes you think, you know I haven't really thought about that.

At the end of the day someone has to use the tool.

So that got me thinking. I have tons of information both internal and external around the reduction of energy usage and the impact upon deferred maintenance but I never really looked at the direct impact upon a FTE.

If you are a traditional business with a single building or a cluster of buildings you most likely have 1 to 2 technical and 1 to 2 mechanical staff members per 1 million square feet.

The average technical staff member will cost you $50,000/yr to $80,000/yr (granted these numbers will shift by location), plus the soft costs of hiring, training, and benefits.

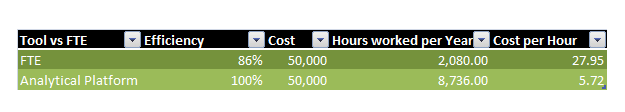

According to the Department of Labor, the average FTE will provide 40 hours of work a week at around 86% efficiency. Thus only 86% (at the high-end) of the salary you are paying and of the hours the FTE is working translate to real business outcomes.

Contrast this to an analytical platform that is focused on continuously commissioning and performing measurement and verification. The average platform for 1 million square feet varies in cost but an acceptable number is $50,000/yr. Looking at a 100% efficiency rate and a 168 hour work week we have a much lower utilization and much greater cost for labor from the FTE.

We can see that there is a significant gap between the cost per hour of using a tool vs using a FTE. However, tools don't run themselves. This in itself is an unfair comparison. What we really need to understand is what the increased impact upon a FTE is when utilizing an analytical tool.

The results shocked me, I was expecting to see that as I moved into larger organizations there was an impact on costs but in smaller organizations there was not. Actually, when I ran the numbers, the results were that in both small and large organizations there was an impact. Furthermore as you move into larger organizations there is actually a smaller impact %wise upon the organization then the immediate impact you see at a smaller company.

The results shocked me, I was expecting to see that as I moved into larger organizations there was an impact on costs and that in smaller organizations there was not.

Analyzing Analytics

Before I summarize the results let me clarify the metrics I set. These metrics were based on experience with clients and external research. I want to clarify I used worst case numbers to provide worst case results. In reality the salaries are usually higher, the costs are lower, and the efficiency of FTE's usually is around 70-75%.

- I set the average cost of a technician at the low-end of the spectrum of $50,000.00

- I set the cost of a platform at the high-end of the spectrum $50,000/yr + $5,000 per FTE.

- I set the efficiency of FTE's at the high-end of the spectrum 86%.

- I set the efficiency of the first year with analytics at 90% to account for a learning curve. That brings total efficiency to 88% on average.

And the Winner is....

- Smaller organizations will see an immediate improvement upon their FTE Efficiency and will see a return on investment within 2 years.

- Medium sized Organizations are the sweet spot and see a return on investment at or below the 1 year mark.

- Large organizations will also see an immediate improvement however the impact starts to decrease around the 10 FTE mark.

- There will always be an impact and as the operational budgets get larger the impact %wise will be smaller but will still offset the cost of a platform within 2 years.

What is This Telling Me

- There is a business decision to be made and even using conservative metrics there is still a 2 year or less payback from the increased efficiency of a analytical platform.

- People have to use the platform and that has a learning curve as well as a culture curve. Even with a modest 2% gain in efficiency we are seeing 2 year or less paybacks.

- Analytics are producing a significant increase in productive hours due to labor being shifted upon the platform. Doing More with Less is being realized.

Doing More with Less is being realized

Which Platform do I select? What Features do I need? How do I Sell this Internally?

This model was built upon the premise that the tool would help in day-to-day tasks that include.

- Maintenance

- Continuous Commissioning

- Measurement and Verification

- Retro Commissioning

Based upon these four criterion, it naturally makes sense that you would target these four CORE options in a RFP or RFQ that you released. Furthermore, you can now ask potential providers to clearly line out how their tool will help you to achieve the above mentioned 4 items. There are many good/free articles on Google about analtyical platforms for buildings. If it comes from a University (.edu), a federal site (.gov) or from blog.buildingautomationmonthly.com ( :D), then it's a safe bet that the information is about as non-biased as you will find.

-----How do I Sell this Internally?----

One of the chief concerns when taking analytics to a company is that change is scary. I remember the first system I programmed back when I first started in this industry. When I first opened my programming tool I thought to myself, "Oh, crap, this is complicated I'm gonna get fired". However, through many painful experiences I grew to be a decent programmer and ultimately moved to teaching people how to program.

One of the chief concerns when taking analytics to a company is that change is scary. I remember the first system I programmed back when I first started in this industry. When I first opened my programming tool I thought to myself, "Oh, crap, this is complicated I'm gonna get fired". However, through many painful experiences I grew to be a decent programmer and ultimately moved to teaching people how to program.

Fact is, there aren't a lot of companies who have analytics deployed on the building systems and so owners, consultants, and technicians have no idea what it is they are getting. Now add to this, that we in the controls field are know to have a persona of I grew up on Pneumatics, analog, (insert old as dirt technology here) and that is the only way to do it! You take that persona, along with the ostrich approach (if I stick my head in the dirt, I won't hear my competitors passing me by) and you get a culture that is resistant to change.

Most owners are in a Pickle, prices are becoming more competitive, there is less buying power in the economy right now, and customers are more informed than ever. An owner has to drive costs down and operate more efficiently but at the same time they have to deal with employees who either:

- View a new tool as a challenge

- View a new tool as a threat

- View a new tool as exposing their lack of work

- View a new tool as an opportunity

Each reaction will require different actions and change management is a huge topic that we will not tackle here. Suffice to say, for employees reporting to you, you will set the expectations, standard, and culture. As for those whom you report to, you will need to use the empirical facts outlined today, along with your knowledge of your company, to build a business case that meets your company's specific needs.

It's a Wrap or maybe a Taco

To conclude, we've laid out how the technology and concepts are already present within the business world, we've outlined how analytics can and will impact a business operations, we've briefly covered the concerns and worries, and we've concluded with a brief look at selling internally.

With technology changing at a rapid clip and business operations under increasing scrutiny it's a given that doing the same thing the same way will not work.

- How are you using technology to change your approach?

- How is it driving outcomes and success in your business?

- What challenges are you facing with adoption and culture?

Let me know your thoughts in the comments below!